Zirconium oxide has many useful properties that allow it to be suitable for a variety of purposes across many industries. The zirconia manufacturing and treatment processes further allow a zirconia injection molding company to modify its characteristics to fit the specific requirements and needs of a wide variety of clients and different applications.

In that respect, zirconium is similar to alumina. Aluminium oxide is also suitable for different uses and alumina can be manufactured and treated in several different ways to cater to different needs. However, the uses, applications, and characteristics tend to differ. Take a look at what zirconium dioxide can be used for and how hard it can be.

What is zirconia oxide?

It’s a crystalline oxide derived from zirconium, which is a transition metal. But is zirconium oxide a metal? The answer is negative. While metals are typically conductive and shiny, ZrO2 is a ceramic material that features properties that are quite the opposite. It works as an excellent electrical insulator and has high thermal resistance.

In addition, it’s an environmentally friendly material because it has a long lifespan and its application in fuel cell technology helps promote clean energy alternatives. This makes it the preferred choice of any zirconia injection molding company that emphasizes greener solutions.

What is zirconium dioxide used for?

Zirconium oxide (ZrO2), or zirconia, is an advanced ceramic material most commonly used in the production of different types of hard ceramics. This material is most widely used for production of various dental implants due to its hardness, chemical unreactivity, and its various biocompatible aspects.

However, zirconia’s use in dentistry is only the most well-known use of this advanced ceramic material. There are other properties that make zirconia suitable for various applications. These properties include:

- Excellent resistance to corrosion and different chemicals

- Absence of innate brittleness of some other types of technical ceramics

- Very high room-temperature strength

- Very high fracture toughness

- High hardness and density

- Very good wear resistance

- Good frictional behavior

- Low thermal conductivity

- Solid electrical insulation

It is these and other characteristics of zirconium dioxide that have made it a common choice not just as the widely-spread material for dental substructures, but also across other industries. Zirconia oxides uses also include:

- Fluid handling

- Aerospace components

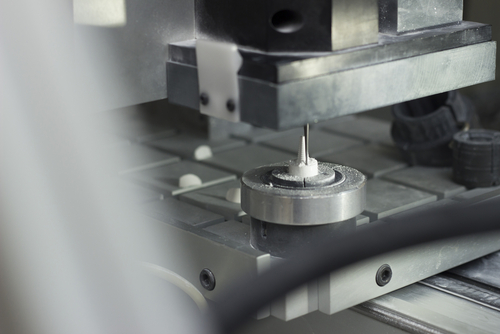

- Cutting tools

- Biomedical applications

- Micro engineering

- Electronics parts

- Fiber optics

- Nozzles for spraying and extrusions

- Parts that require pleasant aesthetic appearance

- Components that require wear resistance and high strength

It is this kind of versatility that makes zirconia one of the most widely used advanced ceramic materials. What’s more, companies are able to manufacture a variety of different parts and components from zirconia, using injection molding, allowing it to become an even more widespread material.

How hard is zirconium oxide?

How hard is zirconium oxide?

Zirconium oxide is an extremely strong material that is also very malleable and ductile. Zirconium oxide shares many physical and chemical properties with titanium, which illustrates how hard and wear-resistant zirconium oxide can be.

For example, when compared to porcelain, zirconium oxide is more than five times as strong, which is one of the reasons it has almost completely replaced porcelain in the dental industry. Coupled with other of its properties of corrosion and wear resistance, zirconium becomes a material that is almost indestructible during everyday use.

What are the benefits of zirconium dioxide?

Apart from its favorable properties, this material offers numerous advantages related to its applications and manufacturing processes:

Design flexibility

It can be engineered to meet the specific requirements of different applications and allows for highly customized solutions in both industrial and consumer applications. It supports complex geometries and innovative designs that can be both aesthetically pleasing and highly functional.

Technological advancements

Its use in medical implants and dental prosthetics allows for technological innovations and results in new treatment options as well as enhanced outcomes. Moreover, in the field of solid oxide fuel cells, it contributes to the development of more efficient and eco-friendly energy solutions.

Enhanced consumer experience

The longevity and performance of consumer products made of this compound lead to higher customer satisfaction and trust in these products.

Improved safety in high-risk applications

Its inherent properties significantly contribute to safer operations in high-risk environments. For example, its use in thermal barrier coatings for gas turbines helps prevent overheating and potential failures. Additionally, in medical applications, its biocompatibility reduces the risk of adverse reactions in patients.

Cost-effectiveness in manufacturing

Because of its resistance to wear and corrosion, and its durability, the components last longer and can reduce the frequency and cost of replacements in industrial applications. In addition, because of advancements in manufacturing techniques such as injection molding, it has become increasingly cost-effective to produce complex parts made of ZrO2.

What is the #1 zirconia injection molding company?

At Wunder Mold, we take advantage of the latest technological advancements in zirconia injection molding and utilize most modern equipment together with tried-and-tested molding procedures to bring all our clients high quality parts and products per their specifications. Our staff consists of dedicated, experienced, and knowledgeable zirconia injection molding professionals who will pay attention to the specific requirements you have in order to provide you with an end-product that will serve your specific purpose perfectly.

Our twenty-five years of experience in the alumina and zirconia injection molding industry has given us the experience necessary to cater to the specific requirements of our clients from many different industries. Contact us by calling (707) 448-2349 or send us an email at sales@wundermold.com.

How hard is zirconium oxide?

How hard is zirconium oxide?