Zirconia is a type of nonmetallic inorganic material that has high corrosion resistance, temperature resistance, abrasion resistance, and exceptional electrical conductivity. In the past half century, it has been heavily invested in the research and development of products made of this material, extending its application to functional and structural components. Today, it is also used by zirconia injection molding companies for highly complex parts with extreme tolerances. Read on to learn more about the structural and functional applications of zirconia ceramics.

What is zirconia ceramic used for?

It has a wide range of applications, from heavy-duty structural parts to high-performance functional tools.

Structural components

Some common applications of ZrO2 ceramics in the field of structural elements include:

Bearings

Bearings made of zirconia ceramic have the characteristics of corrosion resistance, wear resistance, high cold resistance, high temperature resistance, resistance to magnetoelectric insulation, and oil-free self-lubrication. It can be used in special working conditions and in extremely harsh environments.

Bearings made of zirconia ceramic have the characteristics of corrosion resistance, wear resistance, high cold resistance, high temperature resistance, resistance to magnetoelectric insulation, and oil-free self-lubrication. It can be used in special working conditions and in extremely harsh environments.

They have been used in micro cooling fans, significantly improving noise stability and product life, compared to traditional ball and sliding systems.

Valves

Zirconia ceramic valves have excellent thermal shock resistance, high-temperature resistance, corrosion resistance, and wear resistance, and it is suitable for the complicated working conditions of the valve pipeline. In this application, carbon dioxide, hydrogen sulfide, and certain organic acids in reservoir water, oil, and gas can rapidly disable traditionally used metal valves.

Abrasive material

Zirconia ball features low wear rate, high hardness, and long service life, which can significantly reduce the pollution of grinding materials and secure product quality. In addition, the material also features strong impact energy and high density when used for grinding, which can significantly improve the dispersion efficiency of grinding. With good chemical stability, it can also be used in alkaline and acidic media.

Functional components

Their ability to withstand extreme environments makes zirconia ceramics ideal for a variety of functional applications:

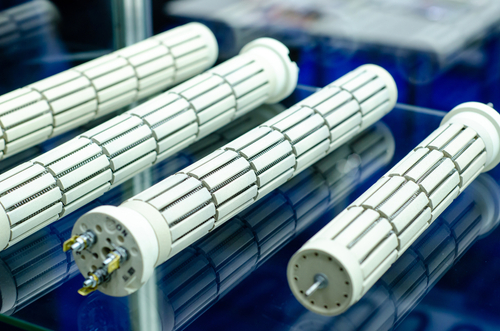

High-temperature heating elements

As an insulating material at room temperature, zirconia has high resistivity and can conduct electricity at temperatures up to 1,112°F. When the temperature reaches above 1,832°F, it can be a good conductor and can be used as a heating element at 3,272°F, with the highest operating temperature at 4,352°F. In fact, it has been successfully used as a heating element and in equipment with oxidation atmospheres above 3,632°F.

Coating material

Together with a stabilizer like yttrium oxide (Y2O3), zirconia thermal barrier is primarily used in high-performance turbine aero-engine. This coating uses corrosion resistance and insulation to protect metal materials, improving fuel combustion efficiency and extending the engine’s life. The coating is also important in other applications, such as aerospace, large thermal power generation, surface ships, and automobile power. It’s also one of the essential technologies in national defense.

Oxygen sensor

In the automotive industry, oxygen sensors make an important part of engines that reduce pollution emissions by using three-way catalytic converters. These sensors automatically detect the oxygen to combustion gas ratio in the engine and control the ratio of input and output gas, significantly reducing the amount of harmful emissions.

What is the best zirconia injection molding company?

What is the best zirconia injection molding company?

Whether you’d like to explore the different grades of alumina, find out more about its durability in harsh conditions, or better understand the properties of zirconia ceramics, our experts at Wunder Mold are here to provide you with all the necessary information and premium-quality parts. We’ll work closely with you to understand the exact requirements of your application and make sure they’re met. Reach out to us by phone or email at sales@wundermold.com and let us know how we can help.

What is the best

What is the best