Numerous favorable properties of advanced ceramic materials make them suitable for electronic devices. They have excellent magnetic and electrical properties and they’re typically smaller and lighter than metallic materials. This is why they’re great for applications in televisions, smartphones, and computers.

A dependable technical ceramics company can produce high-precision quality electronic components such as capacitors, resistors, and substrates. These materials are also used in cutting-edge technologies such as power electronics, LED lighting, and advanced sensors. Continue reading to learn more about the different uses of advanced ceramics in the electronics industry.

What are the uses of technical ceramics in electronics?

These materials include alumina, zirconia, and silicon carbide which possess high thermal conductivity, electrical insulation, and mechanical strength, which makes them extremely favorable for the production of electronic components:

Electronic sensors

These materials combine high thermal stability, corrosion resistance, and strength, which is why they’re typically used for electronic sensors in equipment and machinery with demanding requirements. In these applications, they typically monitor non-electrical variables, including pressure, temperature, distance, flow, moisture content, gas concentration, and acceleration, and convert them into electrical signals. Subsequent electronic components further process these signals.

Ceramic substrate

Due to its excellent dielectric and thermal properties, advanced ceramics are highly suitable for the substrate which is a flat-fired and thin material. There are three types of materials that are typically used and they include beryllium oxide (BeO), aluminum nitride (AlN), and aluminum oxide (Al2O3). These substrates have low dielectric loss and dielectric constant, excellent chemical stability, and high thermal conductivity.

Semiconductors

Advanced ceramics are widely used in the semiconductor industry because of their excellent physical, mechanical, and electrical properties:

- Silicon nitride. Ball bearings made of silicon nitride have low friction, less lubrication, excellent corrosion resistance, and electrical insulation.

- Alumina is thermally and electrically insulating and is widely used in wafer processing equipment.

- Fused silica. The application of fused silica includes wafer carriers, epitaxial silicon deposition reactors, crucibles for drawing silicon ingots, crucibles for wet etch tanks, complex machined parts, and single-wafer processing equipment.

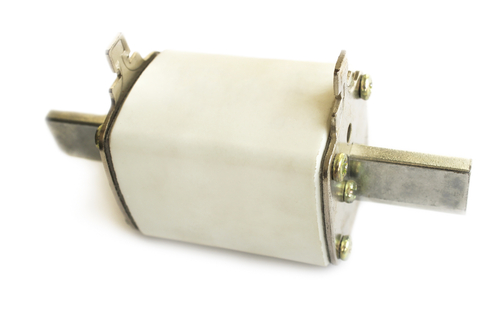

Capacitators

Ceramic capacitors are widely used in electronic circuits as they are stable and provide high capacitance values in a small form factor. They are made of ceramic materials, which provide excellent stability over a wide range of temperatures, frequencies, and voltages.

Resistors and thermistors

Resistors are electronic components that control the flow of current in a circuit by providing resistance, while thermistors are resistors whose resistance changes with temperature. Advanced ceramics provide excellent stability, accuracy, and linearity in these applications, making them ideal for use in precision electronic devices.

Piezoelectric devices

Piezoelectric devices are used in a wide range of electronic applications, including actuators and transducers. Piezoelectric materials have the ability to convert mechanical energy into electrical energy and vice versa, making them ideal for use in devices that require precise movement or sensing. Technical ceramics such as lead zirconate titanate (PZT) and barium titanate (BaTiO3) are commonly used in this production due to their high piezoelectric coefficients and excellent mechanical properties.

Where can I find a reliable technical ceramics company?

Whether you’re interested to learn more about the different industries that use advanced ceramics or want to discover the process behind the quality control during manufacturing, Wunder Mold is the team you can rely on. With our lengthy experience and a team of dedicated and skilled specialists, we provide our clients worldwide with high-precision parts made exactly according to your needs and requirements. We use first-rate technology and premium-quality materials to ensure optimal results. Give us a call today or send us an email at sales@wundermold.com.