Bioceramics possess different desirable properties that make it an excellent choice of material for different sectors within the healthcare industry. In fact, bioceramics are becoming a common area of application for components and parts made through the process of injection molding. There are several reasons behind this growing need. Not only are the properties of different combinations of bioceramic materials suitable for use in the healthcare industry, but the design and manufacturing process allows for constant adjustments to be made to the mold.

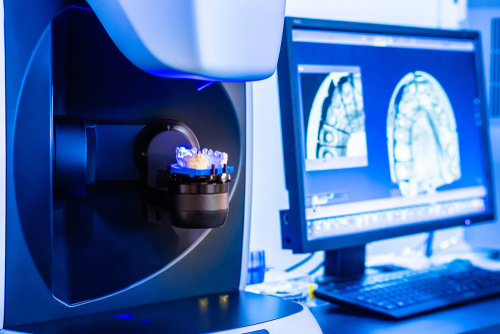

This enables injection molding specialists to fine-tune every single step of the process to ensure production of a medical ceramic component that perfectly fits the specific requirements of medical professionals. That is why it is important to be familiar with what bioceramics actually are, and what properties they have that make them a suitable choice for the healthcare industry.

What are bioceramics?

What are bioceramics?

Bioceramics are a special subclass of advanced ceramics primarily used for various applications in the healthcare industry. Finished bioceramic products are dimensionally stable, antibacterial, anticorrosive, and completely chemically inert, which are properties necessary for different medical uses.

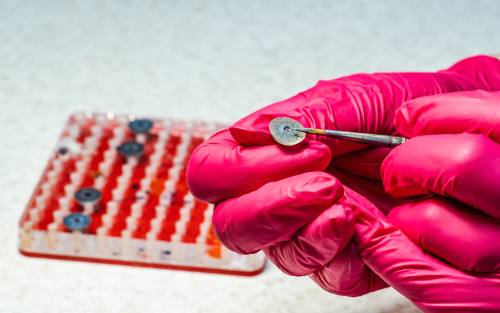

The two most suitable materials used for the manufacturing of bioceramics are zirconia and high-purity alumina. They have the properties necessary to produce adequate bioceramic components. Also, they can be injection-molded into different parts and components, which allows custom designs for a variety of potential applications.

What can bioceramics be used for?

Bioceramics can be used for different purposes, and some of the most common ones include:

- Reconstruction of fractured joints

- Aligning and repairing fractures

- Correcting chronic spinal curvature

- Replacing lost extremities

- Correcting congenital deformities

- Immobilising the vertebrae to protect further damage to the spinal cord

- Restoring alveolar ridge to enhance denture fit

- Replacing loose, damaged, or diseased teeth

- Providing posts for stress application necessary to change deformities

What characteristics should bioceramics have?

- Biocompatibility: The biocompatibility of bioceramic products stem from the fact that the materials used in the manufacturing of bioceramics are chemically inert and antibacterial. What’s more, zirconia is non-toxic to cells, making it one of the most suitable materials for bioceramics.

- Durability: Bioceramic components have to be long-lasting to enable individuals persistent benefits. For example, hip replacement bioceramics need to resist the wear and tear of constant motion and serve their recipients well for a long time.

- Aesthetic properties: Dental application of bioceramics demands aesthetically pleasing components that mimic the look of natural teeth. Zirconia injection molding is able to achieve different looks for various dental implants and components. Also, addition of colors dopant will add the required shade to perfectly match the desired look.

- Radiopacity: Finally, the dental industry requires bioceramics to be easily visible on radiographs, making radiopacity an essential property for all bioceramic components intended for dental applications.

Which company manufactures bioceramic injection molding products for healthcare applications?

Bioceramics are difficult to manufacture right. It is important to use highest-quality injection molding materials and components, as well as to design an adequate injection molding process that will go through all of the necessary manufacturing stages to ensure the end product has all the necessary properties. Bioceramics are mainly used in the healthcare industry, and they demand high precision, durability, and reliability.

Wunder Mold has been producing premium-quality injection-molded components for more than twenty-five years, and we have gained the experience necessary to ensure the end-products match our client’s exact specifications. We will listen to your invaluable input, take the time to carefully design our molding process, and only then begin the actual procedure. Reach out at sales@wundermold.com or call (707) 448-2349.

What are bioceramics?

What are bioceramics?