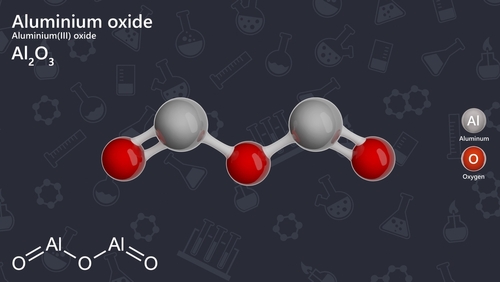

Alumina ceramic is also known as aluminum oxide or just alumina. It’s an industrial ceramic known for its high thermal conductivity and extreme hardness. Due to these and other favorable properties, it’s one of the materials that technical ceramics manufacturers use the most for applications that include corrosive, wear, and structural environments. Keep reading to learn more about its essential properties.

What is the maximum temperature for alumina ceramic?

Generally, alumina ceramics can handle temperatures up to 3,182 degrees Fahrenheit before they start to lose their durability, depending on purity levels. High-purity alumina that’s above 99.5% Al2O3 can endure up to this limit. When it comes to short-term applications, it can even tolerate temperatures approaching 3,272°F. This extremely high tolerance makes them perfect for applications such as furnaces, electrical insulation, and even some medical tools.

Generally, alumina ceramics can handle temperatures up to 3,182 degrees Fahrenheit before they start to lose their durability, depending on purity levels. High-purity alumina that’s above 99.5% Al2O3 can endure up to this limit. When it comes to short-term applications, it can even tolerate temperatures approaching 3,272°F. This extremely high tolerance makes them perfect for applications such as furnaces, electrical insulation, and even some medical tools.

While most metals would melt at these temperatures, alumina maintains its structure, which is why it’s the preferred choice for parts that are exposed to prolonged or intense heat. However, while it’s quite sturdy, when temperatures rise above the limit, it can start to lose its stability, so it’s important to use it within its safe range and allow it to perform well under harsh conditions.

How strong is alumina ceramic?

Alumina is very well-known for its impressive strength which makes it one of the toughest materials available for countless applications, with a compressive strength reaching over 2,000 MPa. It’s strong enough to withstand heavy forces, high pressure, and intense wear and tear without cracking or breaking due to its dense and rigid structure.

For comparison, it’s several times harder than steel, meaning it can handle scratches, friction, and impact better than most metals. Because of this toughness, it’s often used to create parts in industrial machines or armor for protective gear.

What are other properties of alumina ceramic?

Apart from thermal stability and hardness, aluminum oxide boasts other important characteristics, including:

Electrical insulation

Due to its high dielectric strength and low electrical conductivity, it’s an excellent electrical insulator and often used for electrical and electronic components such as insulators, substrates for electronic circuits, and protective casings for high-voltage environments. Its low dielectric loss and stability at high temperatures make it excellent for applications in electronics and telecommunications.

Chemical resistance

Aluminum oxide exhibits excellent resistance to most acids, alkalis, and solvents, which helps it maintain integrity in chemically aggressive environments. This chemical inertness extends its lifespan and reliability, particularly in harsh or corrosive applications. Consequently, this oxide is used in chemical processing, laboratory equipment, and biomedical components, where material longevity and resistance to chemical wear are critical.

Lightweight and low density

With a density of about 3.95 g/cm³, these ceramics are relatively lightweight compared to metals of similar strength. This is why they make an excellent choice where both strength and reduced weight are desirable, such as in aerospace, automotive, and medical devices.

Looking for a reliable technical ceramics manufacturer?

Our services are available to clients worldwide. Feel free to reach out to us by phone or send us an email at sales@wundermold.com to tell us more about your requirements and we’ll work closely with you from start to finish.