In this comprehensive article, we’ll explore the unparalleled versatility of ceramic injection molding across various sectors, ranging from medical and electronics to automotive, filtration, and energy. By understanding the diverse applications and innovations in this field, we can appreciate how ceramic injection molding continues to reshape the landscape of modern manufacturing.

In what industries is ceramic injection molding used?

This versatile manufacturing process finds its application in sectors where the demands for high-precision, durable, and thermally stable components are paramount. Let’s explore the industries that benefit from ceramic injection molding and understand why this advanced technique has become indispensable in their manufacturing processes.

1. Medical industry

The medical field relies on ceramic injection molding for the fabrication of critical components used in surgical instruments, diagnostic equipment, and implants. Ceramics like Alumina and Zirconia offer biocompatibility, corrosion resistance, and excellent wear properties, making them ideal for implantable devices, joint replacements, and dental applications. Furthermore, ceramics’ electrical insulation properties are essential in developing components for imaging and diagnostic equipment, such as X-ray tubes and CT scanners.

2. Electronics and semiconductor manufacturing

The electronics industry benefits greatly from ceramic injection molding for its ability to produce intricate components with high thermal conductivity and electrical insulation. Ceramics like Zirconia are extensively used in manufacturing capacitors, resistors, and insulating substrates, where their dielectric properties contribute to the efficiency and reliability of electronic devices. Moreover, ceramics’ non-conductive nature and resistance to electromagnetic interference make them essential in the production of electronic components for aerospace and telecommunications applications.

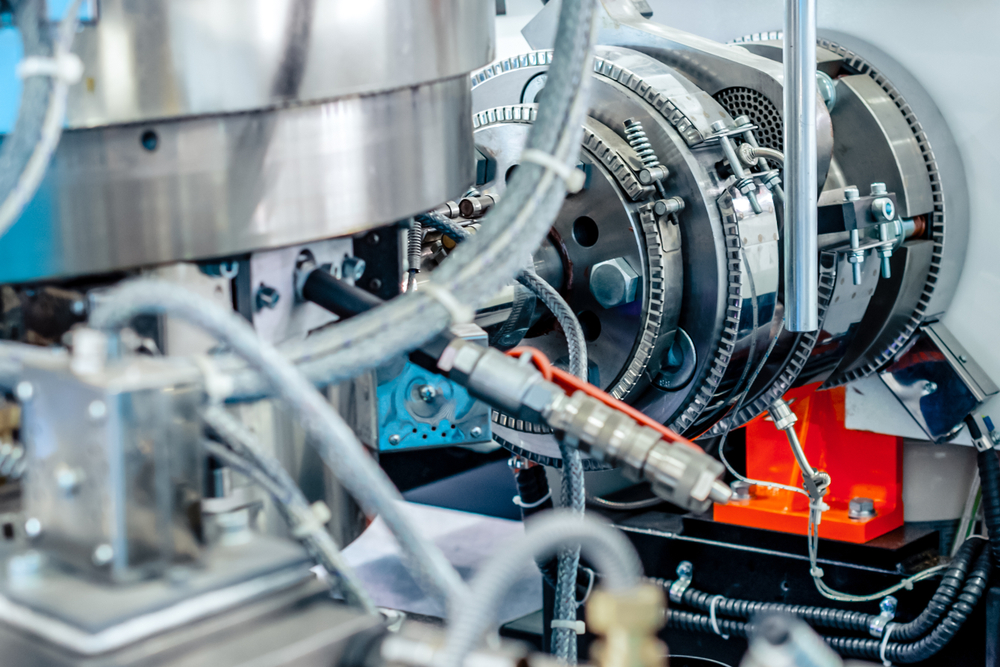

3. Automotive sector

Ceramic injection molding has found its way into the automotive industry, where it plays a significant role in manufacturing components for engine systems and emissions control. Ceramics’ excellent thermal shock resistance and wear properties make them suitable for spark plugs, fuel injection nozzles, and emission control systems. Additionally, lightweight and durable ceramic components contribute to improved fuel efficiency and reduced emissions, aligning with the automotive industry’s growing focus on sustainability.

4. Filtration and separation systems

The filtration industry relies on ceramic injection molding to produce robust and precise filtration components. Ceramics’ porous structure allows for tailored pore sizes and distribution, making them ideal for water purification, air filtration, and chemical separation processes. The chemical and corrosion resistance of ceramics ensures their longevity and efficiency in demanding filtration applications, enabling reliable and effective performance in various industrial settings.

5. Renewable energy applications

In the renewable energy sector, ceramic injection molding plays a crucial role in enhancing the performance and longevity of various energy conversion and storage systems. Ceramics’ electrical and thermal properties make them well-suited for components in solar panels, fuel cells, and batteries. These properties enable efficient energy conversion and storage, contributing to the advancement and sustainability of renewable energy solutions.

6. Power generation and oil & gas

Ceramics are extensively used in power generation equipment such as gas turbines, where their high-temperature stability ensures durability and reliability under extreme conditions. In the oil and gas industry, ceramics’ resistance to corrosion and ability to withstand harsh environments make them suitable for use in downhole tools, drilling components, and refinery processes, contributing to efficient and safe operations.

What is one of the most reputable ceramic injection molding companies?

What is one of the most reputable ceramic injection molding companies?

As a leading technical ceramic manufacturer with a proven track record, Wunder-Mold, we offer unwavering commitment and comprehensive assistance throughout the material selection process, ensuring you find the perfect ceramic material for your specific injection molding project in California or anywhere in the world.

Our team of skilled engineers possesses unmatched expertise in working with ceramics, allowing us to overcome even the most demanding challenges and deliver precise components with exceptional dimensional tolerances. If you’re looking for a reliable manufacturer, we stand ready to empower your business with cutting-edge solutions that exceed your requirements in a broad range of industries. Contact us today at sales@wundermold.com and let us know how we can help!

What is one of the most reputable ceramic injection molding companies?

What is one of the most reputable ceramic injection molding companies?