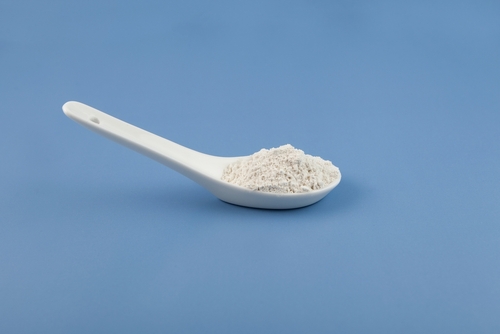

Very well known for their excellent properties, alumina ceramics are widely applied across industries. However, they come in different grades, each offering unique properties, tailored to specific applications.

While the experienced team at your chosen alumina injection molding company will work closely with you to determine the best material for your part, by understanding these variations you can choose the right option for your project, whether you’re dealing with high temperatures, wear resistance, or precision requirements. Continue reading to learn more.

What are the different grades of alumina?

For example, alumina content of 99% or higher features superior thermal resistance, chemical stability, and mechanical strength. On the other hand, lower-purity grades often include additional materials, such as silica or magnesia, which can make them more cost-effective for less demanding applications.

Other factors include grain size, density and porosity. These characteristics can affect the material’s hardness, wear resistance, and thermal conductivity, which allows manufacturers to customize them to suit specific needs.

High purity (99% and above)

High-purity ceramics that typically contain 99% or more alumina, are the top choice for extreme environments. Their exceptional thermal resistance allows them to withstand temperatures that exceed 1832°F and makes them ideal for furnace linings, high-temperature insulators, and components in gas turbines.

In addition, their resistance to chemical corrosion makes them suitable for applications in the chemical and pharmaceutical industries. They are also used in medical applications because of their biocompatibility and mechanical strength. In electronics, they’re highly valued for their electrical insulation properties and are commonly found in substrates, circuit boards, and other components that require thermal and electrical stability.

Mid-range purity (95%-98%)

Mid-range ceramics are a versatile option that balances performance and cost. While they may not offer the extreme capabilities of higher-purity materials, they still provide excellent wear resistance, good thermal stability, and sufficient strength for many industrial applications.

They are often used in cutting tools, pump seals, and industrial nozzles that require wear and abrasion resistance. Their slightly lower cost compared to high-purity alumina makes them an economical choice for applications that don’t require the absolute highest level of performance.

Lower purity (85%-94%)

Lower-purity materials are designed for cost-sensitive applications that still require reliable performance. They often include other materials such as silica or calcium oxide, which reduce the overall cost but maintain acceptable levels of durability and thermal resistance.

Some typical uses include structural components, wear-resistant linings, and basic industrial machinery parts. While they may lack advanced properties of higher grades, they are a practical option for less demanding applications.

How to choose the right grade?

Selecting the right grade highly depends on the specific requirements of your application. It’s best to discuss it in detail with your trusted manufacturers, analyze the specifications, and find the solution that meets all your needs.

What is the best alumina injection molding company?

We work with both domestic and international clients, so give us a call or send us an email at sales@wundermold.com and we’ll be happy to help.