How to Test Ceramic Molded Parts Before Scaling to Volume Production

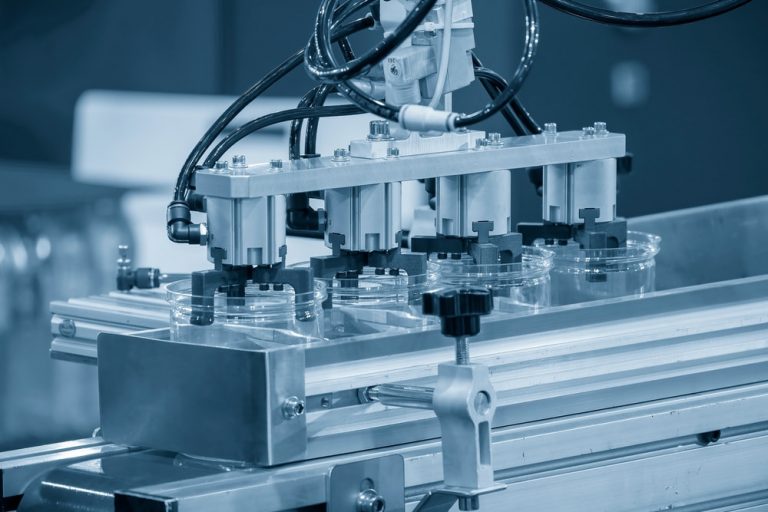

Volume amplifies variation in ceramic molding processes Pilot runs must mirror full production conditions Verify shrinkage, tolerances, and geometry across batches Test strength, thermal behavior, and surface integrity Monitor tool...