What is the use of aluminum oxide in ceramics?

Al2O3 serves various essential roles in enhancing the performance of ceramic materials. Here are some of the most important ones:

Mechanical reinforcement

While ceramic materials are known for their hardness, they can be brittle. When aluminum oxide is incorporated, it acts as a reinforcing agent, increasing the material’s resistance to fracture and improving its toughness. This results in ceramics that are more durable and capable of withstanding mechanical stresses and impacts. This combination can create composite materials with remarkable mechanical strength.

Wear resistance

Aluminum oxide features exceptional hardness which makes it an excellent choice for applications where wear resistance is crucial. When used as a component in ceramics, it provides an added layer of protection against abrasive wear. This is particularly important in applications like cutting tools, grinding wheels, and industrial components subject to harsh environments.

Thermal stability

Al2O3 further enhances the ceramics’ property of high-temperature resistance. It has a high melting point and excellent thermal stability, making it a suitable choice for applications involving extreme heat. This is particularly important in the aerospace, automotive, and electronic industries which require ceramics with thermal insulation properties.

Electrical insulation

As an excellent electrical insulator, Al2O3 is widely used in ceramics in electrical and electronic applications. It prevents the flow of electrical current, making it invaluable for insulating parts, substrates, and components in electronic devices. Moreover, its electrical insulation properties remain stable across a wide range of temperatures.

Biomedical and biocompatible ceramics

In the field of biomedical ceramics, Al2O3 plays an essential role in the development of biocompatible materials. It’s often used in orthopedic and dental implants due to its biocompatibility and resistance to corrosion in biological environments. This ensures that the implanted devices maintain their structural integrity and functionality within the human body.

Corrosion resistance

Aluminum oxide’s high resistance to corrosion makes it ideal for chemically aggressive environments. Ceramics containing this compound can be employed in chemical processing equipment, laboratory apparatus, and industrial settings where exposure to corrosive substances is common.

Its resistance to acidic and alkaline solutions, as well as its ability to withstand the corrosive effects of various chemicals, ensures the longevity and reliability of ceramic components in such applications.

Aesthetic and decorative applications

Beyond its functional roles, aluminum oxide can also be used for aesthetic and decorative purposes in ceramics. It can be employed to create vibrant and durable glazes and pigments for ceramic surfaces, resulting in visually appealing and long-lasting products. It can provide various colors and effects when fired in specific conditions, enhancing the overall aesthetic quality of ceramics.

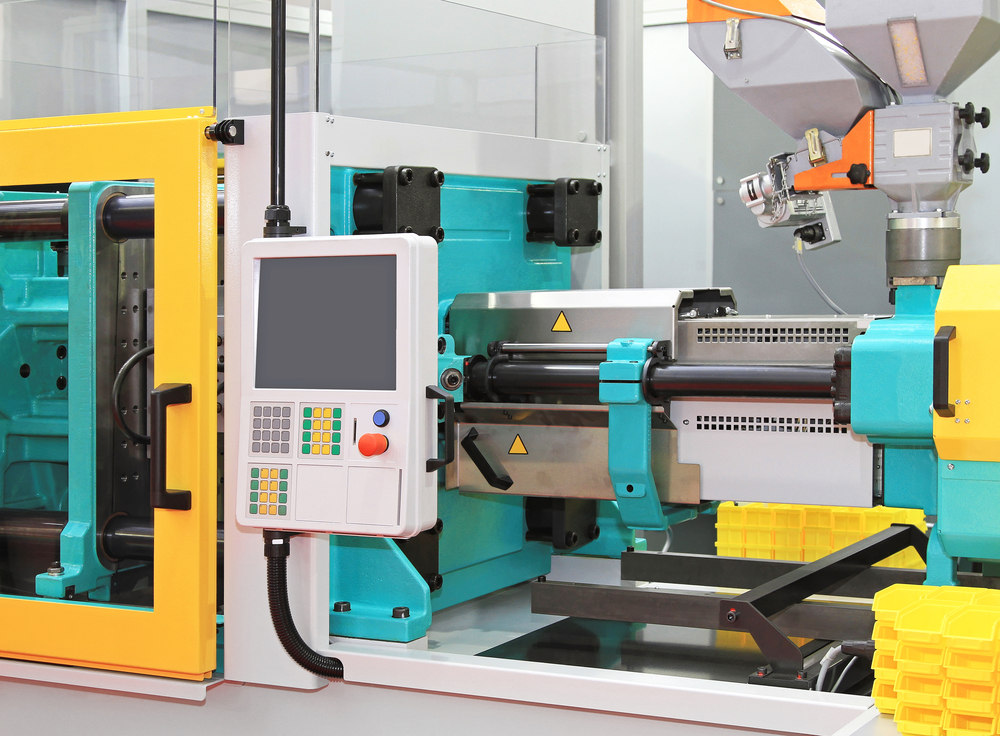

Who provides premium-quality alumina injection molding?

Who provides premium-quality alumina injection molding?

Whether you’re curious about the role of Al2O3 in improving ceramic properties or you’d like to know more about the advantages of aluminum oxide binders in ceramics, professionals at Wunder Mold are here to provide you with the necessary information and high-quality parts. We’ll carefully listen to your needs to give you the results that meet your exact requirements. Email us at sales@wundermold.com or get in touch with us by phone to tell us all about the parts you need.

Who provides premium-quality alumina injection molding?

Who provides premium-quality alumina injection molding?