Successfully designing a part for plastic injection molding is a complicated process that requires experience, knowledge, and a vision. Design can affect the manufacturing costs, component characteristics, and the overall durability and reliability. This is why it’s vital to partner with a plastic injection molding manufacturer capable of designing even the most intricate components with precision and attention to detail. But how do experts actually design these parts?

How do professionals design a part for plastic injection molding?

How do professionals design a part for plastic injection molding?

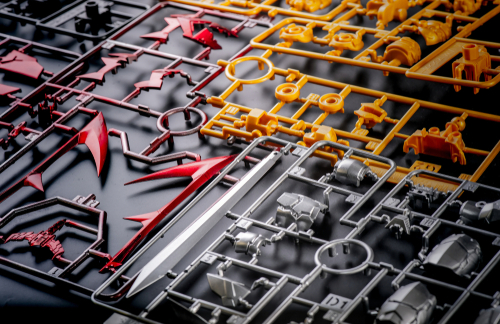

Plastic injection molded components offer numerous advantages, including mass-production uniformity, exceptional scalability, as well as an incredible complexity of parts that professionals can produce. However, all these benefits are only possible if the initial design of the part is good. Here’s what professionals pay attention to when designing a part for plastic injection molding:

Materials

Settling on the choice of materials is one of the first and most important considerations of the design process. Part of this is due to specific chemical or physical properties that make it easy or difficult to achieve and maintain certain tolerances and shapes.

Another part is cost consideration – some materials are more expensive than others but offer advantages that are of no importance to the client. The choice of materials is a combination and compromise between desired characteristics and the cost-effectiveness of the process.

Tolerances

Providing sufficient clearance for tolerance variations can be a significant problem during the design process. Tolerance variations usually depend on tool design, process control, and materials chosen.

Also, parts with tighter tolerances are more expensive to manufacture than parts with normal tolerances. This makes choosing optimal tolerance for the component in question very important for the overall quality and cost of the part.

Sink marks

Avoiding sink marks when manufacturing injection-molded components and parts is a design challenge. Sink marks compromise both the visual aspect and the structural integrity of the finished product, making it a significant consideration for the design stage.

Sink marks depend on additives, materials, surface color and finish, wall thickness, tool quality, and gate location. The designer has to take all these factors into account to ensure a part without sink marks.

Gate location

Gate location is not only critical for sink marks – it affects almost all attributes of plastic injection molded components. Gate location influences wall thickness, surface finish, tolerances, warpage, physical properties, and other characteristics.

Designers implement different strategies for dictating the design and the location of the gate. Also, close collaboration between molders and designers is essential for adequately determining gate location, ensuring no negative effects on the fit, the appearance, and the performance of the finished product.

Uniformity

Depending on the part itself, professionals will try to create a design that features uniform wall thickness throughout the component. This allows them to enhance the flow of the entire process for faster cycle times and turnaround time.

Shut-off angle

Bypass and shutoff angle are terms that describe the minimum angle between the cavity and the core. These angles create openings in those parts that otherwise require cam or slide, which lowers production costs and allows for faster production rates.

Typically, molders specify the largest possible angle between the cavity and the core, while designers want either minimal or no angle at all. They usually compromise with an angle of three to five degrees.

Texturing

Finally, texture of the component is also an important design consideration. Smooth, high-gloss surfaces allow for easier mold ejection, while textured and rough surfaces are more difficult to eject.

Which reputable plastic injection molding manufacturer should I partner with?

Which reputable plastic injection molding manufacturer should I partner with?

Knowing what professional plastic molders take into consideration when designing a part can also help you understand what the price of plastic injection molding depends on. However, you should not stop there and you should also learn more about the main reasons behind defects in plastic injection molded parts and what professionals do to prevent them. Once you have all the information you need, it’s time to find a company to hire.

This is where Wunder Mold steps in. We’re your reliable plastic injection molding company and we manufacture high-quality plastic parts and components that match your precise specifications. With us, you’ll reap all the benefits of outsourcing your plastic molding within the USA and receive a durable part you require. You can contact us by calling (707) 448-2349, or sending an email to sales@wundermold.com.

How do professionals design a part for plastic injection molding?

How do professionals design a part for plastic injection molding? Which reputable plastic injection molding manufacturer should I partner with?

Which reputable plastic injection molding manufacturer should I partner with?